I-hydraulickufanelekile iyisici esixhumanisayo phakathi kwepayipi le-hydraulic kanye nepayipi le-hydraulic, noma phakathi kwepayipi ne-hydraulic element. I-hydraulickufanelekile iqukethe i-hydraulicokokufakat okwepayipi kanye ne-hydraulicokokufaka okweukuhlanganiswa kwe-tube, isixhumi se-hydraulic hose sixhuma ingxenye eyodwa yepayipi le-hydraulic (ebizwa ngokuthi ukuphela komsila) kanye nokuphela kwezinye izingxenye (amatheminali) ukuze kuqinisekiswe ukuhambisana nokuvaleka okungavuzi ngokuhlobene nezinye izingxenye, indawo yokugcina ye-hydraulic hose joint kufanele yakhelwe ngokwezinga le-interface yendawo yonke. Umsebenzi oyinhloko wetheminali ukuqinisekisa ukuvalwa kwesikhathi eside phakathi kwe- okokufakakanye nepayipi.

Kusukela ku-interface ingahlukaniswa ngamafomu alandelayo:

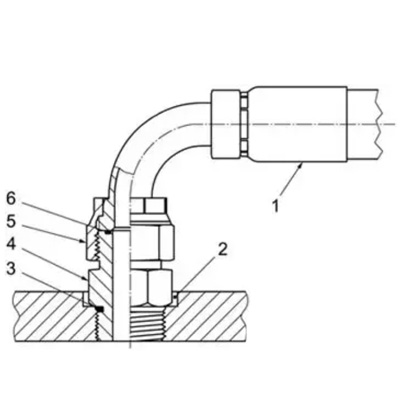

1.Ipayipi le-O-ring face sealokokufaka

1.Ukuhlanganisa ipayipi 2. AmafuthaItheku3. O-ring 4.Ama-adaters5. Amantongomane 6. O-ring

lapho nati 5 is screwed kuya intambo yangaphandleokokufaka, ngokwanda komzuzu wokuqinisa, ubuso bokuphela kwe-hoseokokufakakanye neama-adaptha(ucezu 4) ukucindezela, indandatho ye-o yobuso obu-4 bokuphelaokokufakaikhiqiza ukuguqulwa kwe-elastic, futhi ixhumane ngokugcwele nobuso obu-4 besiqephu sesi-6 kanye nesiqephu sesi-4 futhi ikhiqize ingcindezi yokuvala.

Ukunakwa okukhethekile kufanele kukhokhwe kwinqubo yokufaka, hlola indandatho yokubeka uphawu ngaphambi kokufakwa.

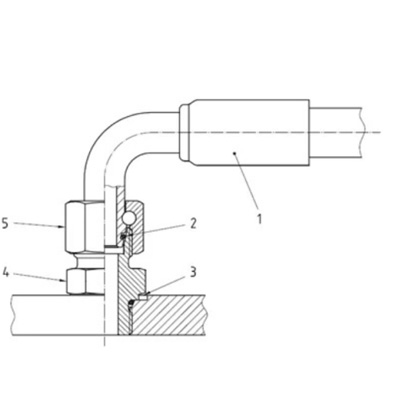

2.24 ° isixhumi se-taper seal end hose

- Ukuhlanganisa ipayipi 2. O-ring 3. AmafuthaItheku 4. I-adaptha 5. Inathi

lapho nati 5 is screwed kuya intambo yangaphandle i-adaptha -Ingxenye 4) , indawo yekhoni yangaphandle yepayipikufanelekile kanye ne-cone yangaphakathi ebusweni be-kufanelekile I-b-Partdy (ingxenye 4) ukuthintana nokucindezela ngokukhuphuka komzuzu wokuqina, i-o-ring ye-conical surface yangaphandle yepayipiokokufaka I-1 ikhiqiza ukuguquguquka okunwebekayo, ithintana ngokuphelele nezindawo eziyi-conical zengxenye 6 kanye nengxenye ye-4 futhi ikhiqize ingcindezi enkulu, esebenza njengophawu, futhi ingcindezi phakathi kwezindawo eziyi-conical inkulu ngenxa yesenzo se-lever sezindawo eziyi-conical, umphumela wokuvala ungcono ngombono.

Ukunakwa okukhethekile kufanele kukhokhwe kwinqubo yokufaka, hlola indandatho yokubeka uphawu ngaphambi kokufakwa.

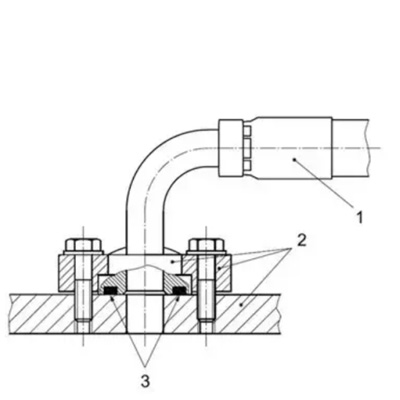

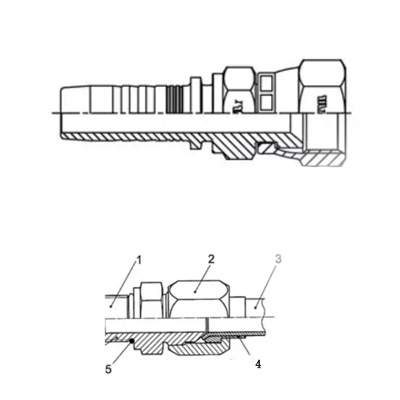

3.Ukufakwa kwepayipi lokuphela kwe-Flanged

I-1.I-Hose couplings 2. I-nozzle yamafutha, ikhanda le-flange, ipuleti lokucindezela kwe-flange 3.Ikhanda le-flange le-hose joint licindezelwa ku-orifice yamafutha ngepuleti yokucindezela ye-flange.

Lapho umzuzu wokuqina webhawodi ukhula, ibhawodi likhiqiza amandla amakhulu okuqinisa ngaphambili. Amandla okuqinisa ngaphambili webhawodi adlula kupuleti lomfutho we-flange, ucindezela ikhanda le-flange ngokuqinile ku-orifice kawoyela, i-o-ring (Ingxenye 3) esekhanda le-flange icindezelwe ukuze igxumeke, futhi ipayipi elihlangene -Ingxenye 1) inokuxhumana okwanele phakathi kobuso bokuphela kwe-flange kanye ne-oil nozzle surface ukukhiqiza ingcindezi, esebenza njengophawu, ngenxa yokusetshenziswa kwamabhawudo anamandla amakhulu, ukucindezela phakathi kwezindawo zokuxhumana kuphezulu kakhulu futhi umphumela wokuvala muhle kakhulu umbono.

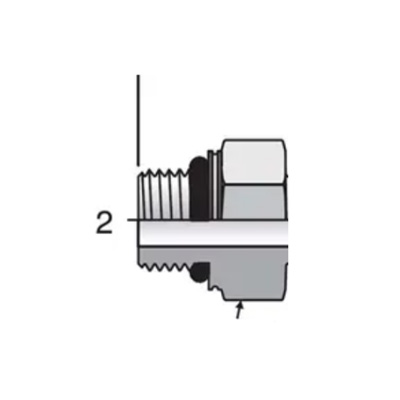

4.Ukufakwa kwe-stud end hose

Umsuka wentambo yei-adapthaihlinzekwa ngewasha yohlobo lwe-O. Uma ilunga lixhunywe nembobo kawoyela ngentambo, indandatho yohlobo lwe-O inamathela ekugcineni kwembobo kawoyela ukuze idlale indima yokuvala.

5.37 ° yavutha isixhumi sepayipi lokugcina

1. Ukuhlanganisa ipayipi 2. AMAKI 3. Ipayipi lensimbi 4.

lapho i-nati 2 igoqwe emculweni wangaphandle womzimba ohlangene (ucezu 1), ngokukhula komzuzu wokuqina, indawo yangaphandle yekhoni yokuxhumana okuhlangene kwepayipi futhi ihlanganiswe ne-cone yangaphakathi yepayipi yensimbi (isiqephu 3 ), i-hose joint 1 piece 3 cone ukuxhumana okugcwele futhi ikhiqize ingcindezi enkulu, idlala indima yokuvala uphawu, ngenxa ye-cone ye-lever, ukucindezela phakathi kwe-cone kukhulu. Enqubweni yokukhetha inhlanganisela yepayipi ye-hydraulic, sidinga ukucabangela ingcindezi ephezulu yokusebenza, izinga lokushisa lokusebenza, usayizi wesixhumi esibonakalayo, usayizi wepayipi ofanele, ukuthi ngabe ukufakwa kulula, umnotho nezinye izici. Ukucindezela okukhulu kokusebenza kwe-joint akumele kube ngaphansi kokucindezela okukhulu kokusebenza kwe-hose.

Isikhathi sokuthumela: Nov-28-2023